Holding Problems

This type of equipment is also designed to expand or contract parallel, and therefore introduce the same problems as diaphragm chucks and ground chuck jaws as well as the possible error from dirt and chips.

When the collet is actuated it moves away from the basic mandrel, and grit, dirt and chips may get between the collet and the mandrel, thus losing accuracy. Wear on the mandrel taper also takes place and introduces still further error.

Tools of this type made a great step forward in eliminating the dirt problem and are much more accurate than the open or split type. However, the main problem, inability to achieve total surface contact on approximately 90% of production parts, is still to be found here.

The mechanical movement stops when the expansion picks up the smallest diameter of the hole or the largest diameter of the contacting surface, thereby giving only line contact.

Another problem with this type of arbor or chuck is that expansion is accomplished by stressing metal against metal. This causes work hardening of the sleeve and produces very short tool life.

This analysis of the available types of tools attempts to explain why it is so difficult to produce close tolerances even with the best and newest of machine tools. Is it possible then to apply tooling to these close tolerance jobs which will transfer spindle accuracy through the part tolerance, absorbing that inaccuracy every time and give spindle accuracy at the work surface?

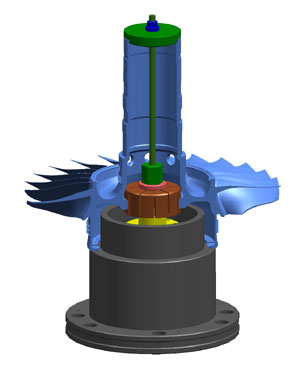

- With Jerry Tools' arbors and chucks you can overcome most of these problems. Jerry Tools arbors and chucks have no openings or external moving parts and thus eliminate the dirt and chip problem.

- Jerry Tools arbors and chucks expand within the elastic limits of the steel of which they are made and therefore will not harden or distort.

- Jerry Tools products have their own built-in hydraulic system and require no outside source of oil pressure.

- Jerry Tools products expand or contract to conform to the shape of the locating surface. They pick up taper, out of roundness, bell mouth holes, barrel shaped holes, or conform to any shape within their expanding limits. While conforming to these shapes they maintain spindle accuracy to the working surface; eliminating the manufacturing tolerances of conventional holding devices. In addition, tool chatter is reduced to a minimum because the work is, in effect, held within a thin layer of fluid under the steel expansion sleeve. This fluid acts as a dampening component, absorbing most tool chatter.

- Jerry Tools products are practically maintenance free. If repairs are required, tools can be reworked, sleeves replaced, or other repairs made here at the factory fast and easy. Many components are standard shelf items, with quick turn around on minor repairs.