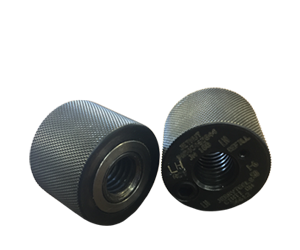

Jetnuts

Jetnut hydraulic nuts are spun on threaded shafts by hand until snug. Pressure is then actuated hydraulically by a furnished 6 ounce gun. This gun is the only tool needed; sledgehammers, wrenches and hammers that can damage the locking nut are not necessary. Pressure is distributed evenly over the surface because of hydraulic pressure within the nut body.

The contacting surface of the nut has the ability to "cock" within the nut body, thereby eliminating any out of square condition that may exist between the surface being clamped and the pitch diameter of the thread.

The higher holding pressures distributed evenly over the mating surfaces make the shaft stiffer and stronger. This causes the shaft to run truer. Removal of the nut is easily accomplished by opening a small ball check which allows pressure relief. The nut is then simply spun off the shaft by hand.

Used throughout the industry, A partial listing of Jetnut users include slitting mills, rolling mills, hobb arbors, fixtures, bearing retainers, horizontal mills, abrasive machinery, cut-off machinery, oil field rigs, pumps, punch presses, ship and shipyard applications and numerous other uses wherever lock nuts are required in manufacturing

- Jerry Tools Jetnut eliminate stripped threads...extend knife life...never back off...eliminate knife wobble and are safer than traditional methods to improve the total slitting operation.

- The Jetnut hydraulic abrasive wheel clamp insures positive, no-slip drive and quick release for wheel change.

- The Jerry Tools Jetnut improves run out on precision arbors and keeps the operator from damaging arbors.

- Quick release for changing is made possible with the Jetnut because it never backs off, assuring maximum safety.